Understanding Heat Press PU Vinyl: A Comprehensive Guide for Professionals

Jul 16,2025

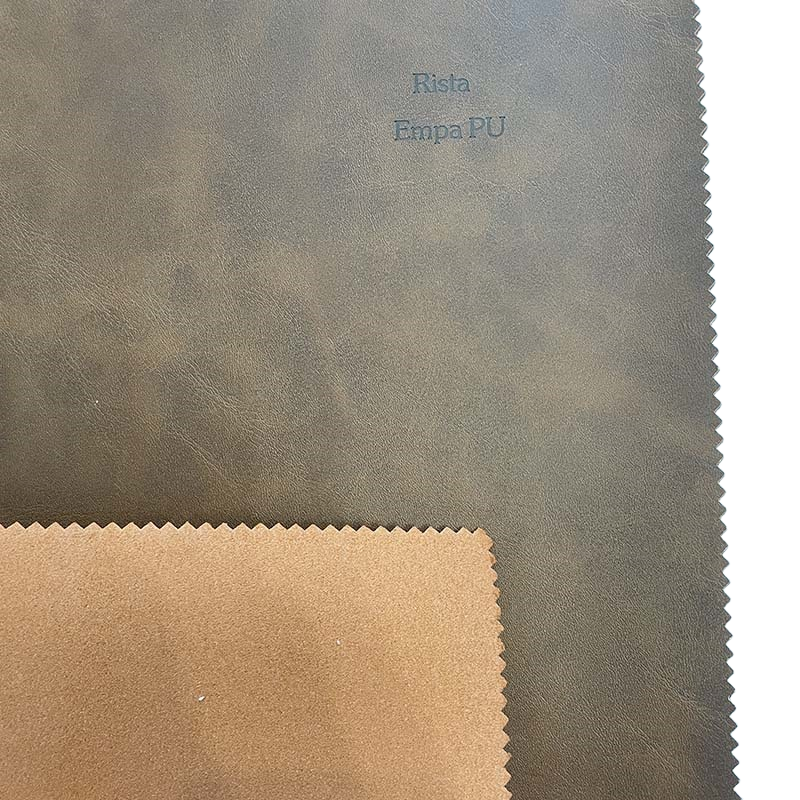

Heat press PU vinyl has gained significant popularity in the textile industry, particularly for applications involving synthetic leather and other leather alternatives. This innovative material is known for its versatility and ease of use, making it a favored choice among professionals looking to create high-quality designs on various substrates.

Primarily, heat press PU vinyl is a polyurethane-based material that can be easily cut into shapes or designs using a vinyl cutter. Once the desired design is prepared, it is applied to surfaces through a heat press machine, which uses heat and pressure to bond the vinyl to the substrate. This method is particularly advantageous for producing custom apparel, promotional items, and even intricate designs on synthetic leather products.

One of the key benefits of using heat press PU vinyl is its durability. Unlike traditional printing methods, heat transfer vinyl tends to hold up well against wear and tear, ensuring that designs remain vibrant and intact even after repeated washing or use. Additionally, PU vinyl is often softer and more flexible than other vinyl options, which makes it more comfortable against the skin for apparel applications.

Another noteworthy advantage of heat press PU vinyl is its compatibility with a variety of fabrics. It can be used effectively on cotton, polyester, and blends, making it a versatile option for different projects. This flexibility allows professionals to experiment with various materials without compromising the quality of the final product.

When working with heat press PU vinyl, it’s essential to consider the temperature and pressure settings of the heat press machine. Properly calibrating these parameters is crucial to achieving optimal adhesion and ensuring that the vinyl does not scorch or damage the substrate. For best results, refer to the manufacturer's guidelines regarding recommended settings for different materials.

It's also important to note that heat press PU vinyl is available in a wide range of colors and finishes, including matte, glossy, and even metallic options. This diversity allows professionals to unleash their creativity and tailor their designs to meet specific client needs. Furthermore, layering different colors of PU vinyl can produce stunning, multi-dimensional effects that are visually striking.

In conclusion, heat press PU vinyl offers a dynamic solution for professionals in the textile and synthetic leather industries. Its durability, compatibility with various fabrics, and aesthetic versatility make it an ideal choice for creating custom designs. By understanding its properties and best practices, one can leverage heat press PU vinyl to elevate the quality of their products and meet the evolving demands of the market. Embracing this innovative material can significantly enhance the creative potential of your projects.

Primarily, heat press PU vinyl is a polyurethane-based material that can be easily cut into shapes or designs using a vinyl cutter. Once the desired design is prepared, it is applied to surfaces through a heat press machine, which uses heat and pressure to bond the vinyl to the substrate. This method is particularly advantageous for producing custom apparel, promotional items, and even intricate designs on synthetic leather products.

One of the key benefits of using heat press PU vinyl is its durability. Unlike traditional printing methods, heat transfer vinyl tends to hold up well against wear and tear, ensuring that designs remain vibrant and intact even after repeated washing or use. Additionally, PU vinyl is often softer and more flexible than other vinyl options, which makes it more comfortable against the skin for apparel applications.

Another noteworthy advantage of heat press PU vinyl is its compatibility with a variety of fabrics. It can be used effectively on cotton, polyester, and blends, making it a versatile option for different projects. This flexibility allows professionals to experiment with various materials without compromising the quality of the final product.

When working with heat press PU vinyl, it’s essential to consider the temperature and pressure settings of the heat press machine. Properly calibrating these parameters is crucial to achieving optimal adhesion and ensuring that the vinyl does not scorch or damage the substrate. For best results, refer to the manufacturer's guidelines regarding recommended settings for different materials.

It's also important to note that heat press PU vinyl is available in a wide range of colors and finishes, including matte, glossy, and even metallic options. This diversity allows professionals to unleash their creativity and tailor their designs to meet specific client needs. Furthermore, layering different colors of PU vinyl can produce stunning, multi-dimensional effects that are visually striking.

In conclusion, heat press PU vinyl offers a dynamic solution for professionals in the textile and synthetic leather industries. Its durability, compatibility with various fabrics, and aesthetic versatility make it an ideal choice for creating custom designs. By understanding its properties and best practices, one can leverage heat press PU vinyl to elevate the quality of their products and meet the evolving demands of the market. Embracing this innovative material can significantly enhance the creative potential of your projects.