Understanding Heat Press PU Vinyl: A Guide for Textile and Leather Industries

Feb 16,2025

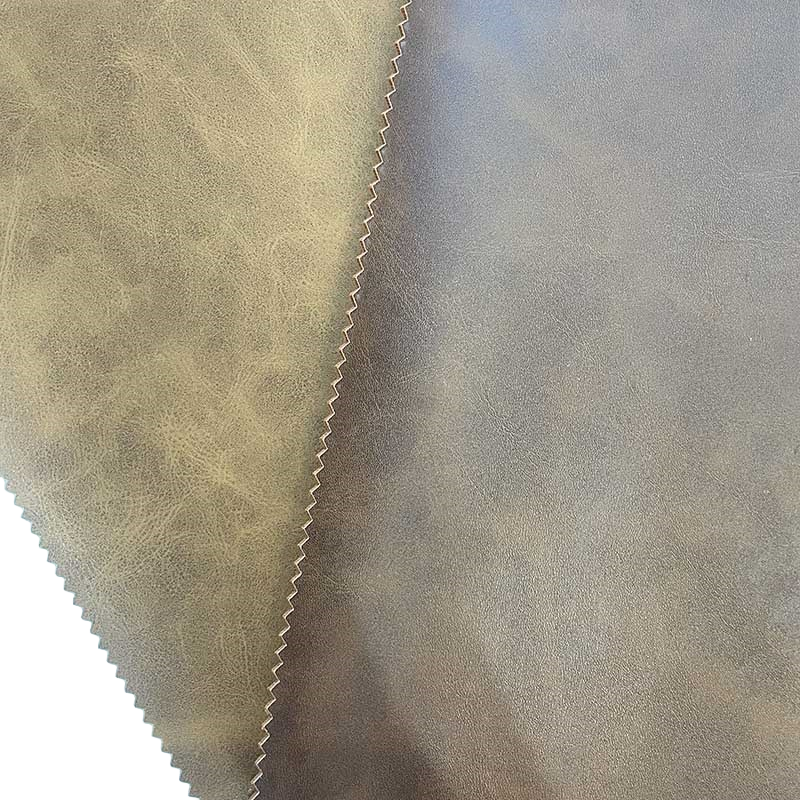

Heat press PU vinyl, short for polyurethane vinyl, is a popular material in the textile and leather industries due to its versatility and durability. This material is primarily used in heat transfer applications, where designs and patterns are applied to fabrics and leather using heat and pressure. Understanding the properties and uses of heat press PU vinyl can enhance your product offerings and improve your production processes.

One of the primary advantages of heat press PU vinyl is its flexibility. Unlike other materials, PU vinyl can easily conform to various shapes and surfaces, making it ideal for a wide range of applications, from custom apparel to leather goods. This adaptability allows manufacturers to create intricate designs with ease, which is especially beneficial in the fashion and promotional industries.

In addition to its flexibility, heat press PU vinyl is known for its durability. When correctly applied, the vinyl adheres securely to the substrate, ensuring that the design withstands repeated washings and wear over time. This longevity makes it a favored choice among businesses aiming to provide high-quality products to their customers.

The application process for heat press PU vinyl is straightforward, requiring a heat press machine that can accurately control temperature and pressure. It is crucial to follow the manufacturer's specifications for the best results. Typically, the heat press should be set to a temperature range of 150-170 degrees Celsius (302-338 degrees Fahrenheit), with an application time of approximately 10-15 seconds. An even pressure across the design is also vital to ensure proper adhesion.

Another important aspect to consider is the type of fabric or leather being used. Heat press PU vinyl adheres well to cotton, polyester, and blends, but it is essential to test compatibility on synthetic leathers or coated materials to prevent damage. Pre-heating the substrate before applying the vinyl can also enhance adhesion, as it helps eliminate moisture and prepares the surface for the design.

Cleaning and maintaining products made with heat press PU vinyl is relatively easy. Most items can be machine-washed on a gentle cycle, but it is advisable to avoid fabric softeners and bleach. Additionally, air-drying is recommended to prolong the lifespan of the vinyl. If the design begins to lift or wear, it can often be repaired by reapplying heat with a press cloth over the affected area.

In conclusion, heat press PU vinyl serves as a versatile and robust option for various applications in the textile and leather industries. By understanding its properties and following proper application techniques, manufacturers can produce high-quality products that meet customer expectations. Whether creating custom clothing or designing leather accessories, heat press PU vinyl is an invaluable tool for enhancing creativity and durability in your offerings.

One of the primary advantages of heat press PU vinyl is its flexibility. Unlike other materials, PU vinyl can easily conform to various shapes and surfaces, making it ideal for a wide range of applications, from custom apparel to leather goods. This adaptability allows manufacturers to create intricate designs with ease, which is especially beneficial in the fashion and promotional industries.

In addition to its flexibility, heat press PU vinyl is known for its durability. When correctly applied, the vinyl adheres securely to the substrate, ensuring that the design withstands repeated washings and wear over time. This longevity makes it a favored choice among businesses aiming to provide high-quality products to their customers.

The application process for heat press PU vinyl is straightforward, requiring a heat press machine that can accurately control temperature and pressure. It is crucial to follow the manufacturer's specifications for the best results. Typically, the heat press should be set to a temperature range of 150-170 degrees Celsius (302-338 degrees Fahrenheit), with an application time of approximately 10-15 seconds. An even pressure across the design is also vital to ensure proper adhesion.

Another important aspect to consider is the type of fabric or leather being used. Heat press PU vinyl adheres well to cotton, polyester, and blends, but it is essential to test compatibility on synthetic leathers or coated materials to prevent damage. Pre-heating the substrate before applying the vinyl can also enhance adhesion, as it helps eliminate moisture and prepares the surface for the design.

Cleaning and maintaining products made with heat press PU vinyl is relatively easy. Most items can be machine-washed on a gentle cycle, but it is advisable to avoid fabric softeners and bleach. Additionally, air-drying is recommended to prolong the lifespan of the vinyl. If the design begins to lift or wear, it can often be repaired by reapplying heat with a press cloth over the affected area.

In conclusion, heat press PU vinyl serves as a versatile and robust option for various applications in the textile and leather industries. By understanding its properties and following proper application techniques, manufacturers can produce high-quality products that meet customer expectations. Whether creating custom clothing or designing leather accessories, heat press PU vinyl is an invaluable tool for enhancing creativity and durability in your offerings.