Top Benefits of Using Hot Stamping for PU Leather Products

Jan 26,2025

Top Benefits of Using Hot Stamping for PU Leather Products

Introduction to Hot Stamping in PU Leather Manufacturing

Hot stamping, a versatile printing technique, has gained immense popularity in the production of PU leather products. This method uses heat and pressure to apply decorative elements, such as logos and patterns, onto the surface of PU leather. As more manufacturers adopt this technique, understanding the benefits it offers becomes crucial for both businesses and consumers.

In this article, we will delve into the numerous advantages of hot stamping for PU leather products, exploring its impact on aesthetics, durability, and overall marketability.

What is PU Leather and Why Choose It?

Understanding PU Leather

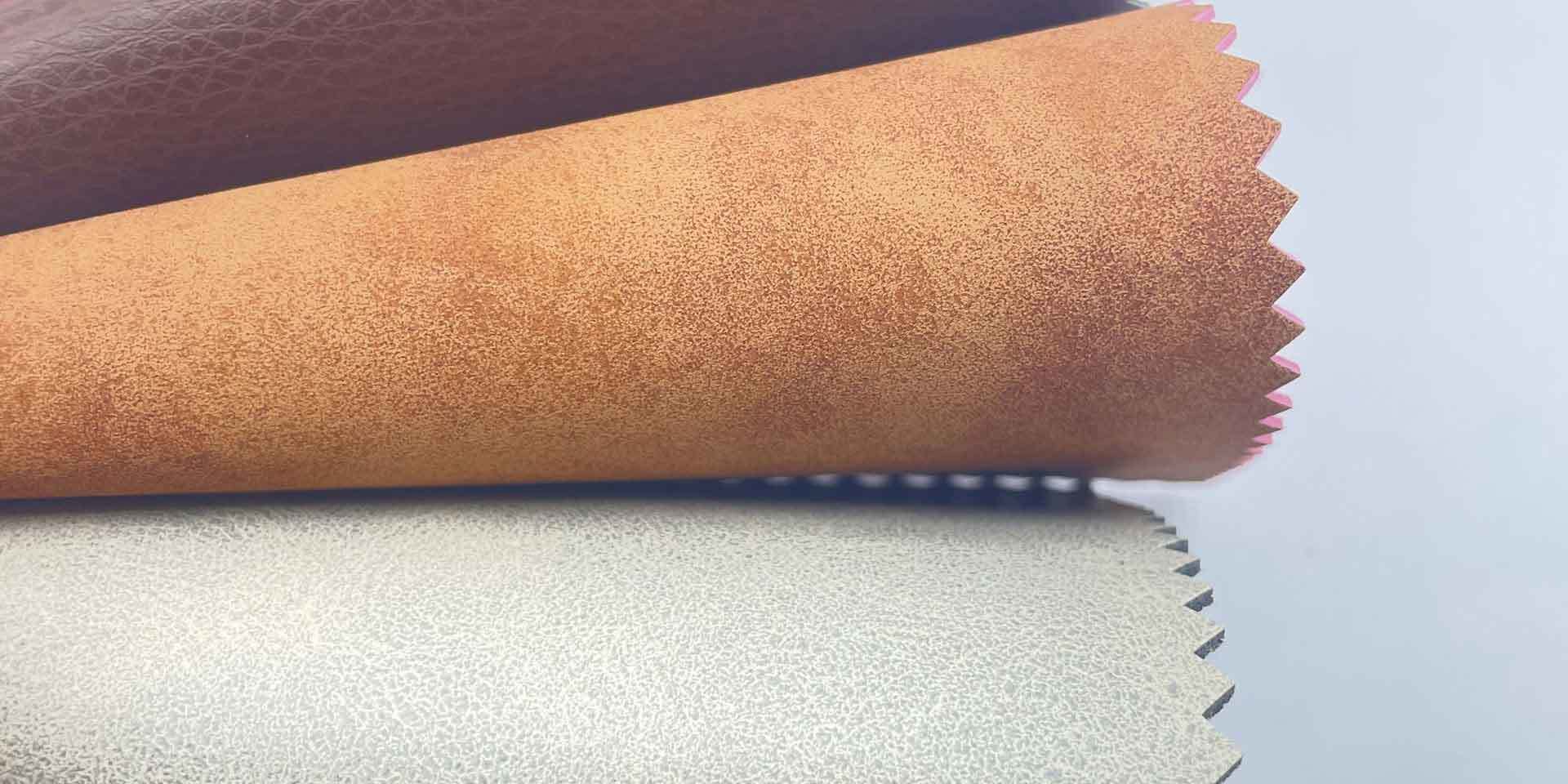

PU leather, or polyurethane leather, is a synthetic alternative to genuine leather. Made from a base material coated with a layer of polyurethane, it offers a similar look and feel to real leather at a more affordable price point. The demand for PU leather has surged due to its ethical considerations, ease of maintenance, and versatility in design.

Benefits of PU Leather

1. **Eco-Friendly Option**: PU leather is considered more environmentally friendly compared to traditional leather, as it does not involve animal cruelty.

2. **Cost-Effective**: It is typically less expensive than genuine leather, making it accessible to a wider audience.

3. **Easy to Clean**: PU leather can be easily wiped down with a damp cloth, offering convenience for everyday use.

4. **Variety of Styles**: This material can be manufactured in numerous colors and textures, allowing for creative design possibilities.

What is Hot Stamping?

Hot stamping, also known as foil stamping, is a decorative technique where metallic or colored foils are transferred onto a surface using heat and pressure. This process is widely used in various industries, including fashion, automotive, and packaging, to enhance product appeal.

How Hot Stamping Works

During the hot stamping process, a heated die is pressed onto a foil and the surface of the PU leather. The heat activates the adhesive on the foil, causing it to stick to the surface. This results in a vibrant, high-quality finish that is both visually appealing and durable.

Key Benefits of Hot Stamping for PU Leather Products

Aesthetic Appeal

1. **Enhanced Visuals**: Hot stamping provides a striking finish that can elevate the appearance of PU leather products, making them stand out in a crowded market.

2. **Customization Options**: Brands can create unique designs tailored to their customers' preferences, increasing product appeal and brand recognition.

3. **Variety of Foil Choices**: Available in numerous colors and finishes, including matte, glossy, and metallic, hot stamping allows for creative expression in product design.

Durability and Longevity

1. **Resistance to Wear and Tear**: Hot stamping creates a bond that is highly resistant to abrasions and scratches, ensuring the designs remain intact over time.

2. **Weather Resistance**: The heat-sealed designs are less prone to fading due to exposure to sunlight or moisture, making them ideal for outdoor applications.

3. **Low Maintenance**: Hot-stamped products are easy to clean and maintain, helping to preserve their appearance for longer periods.

Cost-Effectiveness

1. **Reduced Production Costs**: Hot stamping can offer cost savings in production compared to other decorating methods, such as screen printing or embroidery.

2. **Efficient Process**: The quick application of designs allows for faster production times, enabling manufacturers to meet demand efficiently.

3. **Minimized Waste**: This process generates less waste than traditional printing methods, aligning with sustainable practices.

Versatile Applications

1. **Wide Range of Products**: Hot stamping can be applied to various PU leather items, including bags, wallets, shoes, and apparel.

2. **Branding Opportunities**: Businesses can utilize hot stamping to enhance branding by incorporating logos and other promotional elements seamlessly into their products.

3. **Product Differentiation**: With unique hot-stamped designs, products can be differentiated in a competitive marketplace, attracting a larger customer base.

Hot Stamping Techniques for PU Leather

Choosing the Right Foil for Hot Stamping

Selecting the appropriate foil type is critical for achieving the desired results. Foils vary in color, finish, and adhesive properties, allowing for a wide array of creative possibilities.

Temperature and Pressure Settings

Proper control of temperature and pressure during the hot stamping process is crucial for ensuring optimal adhesion and finish quality. Manufacturers must calibrate their machines to prevent damage to the PU leather while achieving a perfect bond.

Design Considerations

When designing for hot stamping, it’s essential to consider factors such as complexity, size, and placement of the design. Simple designs with bold lines often yield the best visual impact, while intricate designs may require careful planning to ensure clarity.

Challenges and Considerations

Limitations of Hot Stamping

While hot stamping offers numerous benefits, it’s essential to acknowledge some limitations. Certain PU leather types may not hold up well under high temperatures, leading to potential damage. Conducting tests on sample materials before large-scale production is advisable.

Environmental Considerations

Although PU leather is a more sustainable option than genuine leather, the hot stamping process must also consider environmental impacts. Choosing eco-friendly foils and adhering to sustainable production practices can help mitigate any negative effects.

Conclusion

In summary, hot stamping presents a multitude of benefits for PU leather products, from enhancing aesthetic appeal to improving durability and cost-effectiveness. As the demand for customizable, high-quality PU leather items continues to grow, manufacturers and consumers alike should consider the advantages of integrating hot stamping into their product offerings.

By understanding the nuances of this printing technique, businesses can not only elevate their branding but also remain competitive in a dynamic market. Combining PU leather's versatility with the vibrant finishes achievable through hot stamping can lead to innovative and attractive products that resonate with consumers.

FAQs

1. What types of products can be enhanced with hot stamping?

Hot stamping can be applied to a variety of PU leather products, including bags, wallets, belts, shoes, and even apparel.

2. Is hot stamping environmentally friendly?

While PU leather is considered more sustainable than genuine leather, the environmental impact of hot stamping depends on the materials and processes used. Opting for eco-friendly foils can minimize negative effects.

3. How does hot stamping compare to other printing methods?

Hot stamping offers a more durable and visually striking finish compared to other methods such as screen printing or embroidery, making it a preferred choice for many manufacturers.

4. Can hot stamping be done on all types of PU leather?

Not all PU leather is suitable for hot stamping. It's essential to test the material beforehand to ensure compatibility with the heat and pressure of the process.

5. What is the cost of implementing hot stamping in production?

The cost can vary based on factors such as the complexity of the design, the type of foil used, and the scale of production. However, hot stamping often results in overall cost savings due to reduced production times.