Transform Your Creations: The Ultimate Guide to Heat Pressing Leather Sheets

Jan 14,2025

Transform Your Creations: The Ultimate Guide to Heat Pressing Leather Sheets

Table of Contents

- Introduction to Heat Pressing Leather Sheets

- What is Heat Pressing?

- Benefits of Heat Pressing Leather Sheets

- Types of Leather Sheets Suitable for Heat Pressing

- Essential Tools and Equipment for Heat Pressing

- Step-by-Step Guide to Heat Pressing Leather Sheets

- Troubleshooting Common Heat Pressing Issues

- Creative Uses for Heat Pressed Leather Projects

- Conclusion

- FAQs About Heat Pressing Leather Sheets

Introduction to Heat Pressing Leather Sheets

Heat pressing leather sheets has become a popular craft technique that combines both art and technology. This method involves using a heat press machine to apply heat and pressure to leather, resulting in beautifully decorated and personalized items. Whether crafting unique gifts, custom designs, or professional-quality products, heat pressing enables creators to push the boundaries of traditional leatherwork. In this guide, we will explore everything you need to know about heat pressing leather, from the basics to advanced techniques.

What is Heat Pressing?

Heat pressing is a method of applying heat and pressure to various materials, including fabric and leather, to create designs, patterns, or graphics. The process typically involves a heat press machine, which consists of two heated plates: one on top and one on the bottom. When the plates close, they apply consistent pressure and heat to the material, allowing the transfer of inks, foils, or other decorative elements onto the surface.

Unlike traditional sewing or stitching, heat pressing provides a clean and professional finish that enhances the aesthetic appeal of leather projects. The versatility of heat pressing allows for the incorporation of intricate designs and vibrant colors, making it an ideal choice for both hobbyists and professionals.

Benefits of Heat Pressing Leather Sheets

Heat pressing leather sheets presents numerous advantages for crafters and artisans. Here are some of the key benefits:

1. Professional Finish

Heat pressing offers a smooth, polished finish that sewing or gluing often cannot achieve. It allows for precise application of designs, ensuring a clean and professional look.

2. Versatility

From logos to intricate patterns, heat pressing accommodates a wide range of designs and colors. This versatility enables creators to experiment and innovate with their projects.

3. Time Efficiency

Heat pressing can be faster than traditional methods, allowing artisans to produce high-quality items quickly. This efficiency is particularly beneficial for small businesses or those with high production demands.

4. Increased Durability

Products made using heat pressing are often more durable and resistant to wear. The heat adheres designs firmly to the leather, reducing the likelihood of peeling or fading over time.

Types of Leather Sheets Suitable for Heat Pressing

Not all leather is created equal when it comes to heat pressing. Understanding which types of leather work best is crucial for achieving optimal results. The following are the most common types of leather sheets suitable for heat pressing:

1. Genuine Leather

Genuine leather is durable and has a natural look, making it a popular choice for heat pressing. It holds designs well and can withstand the heat and pressure of the process.

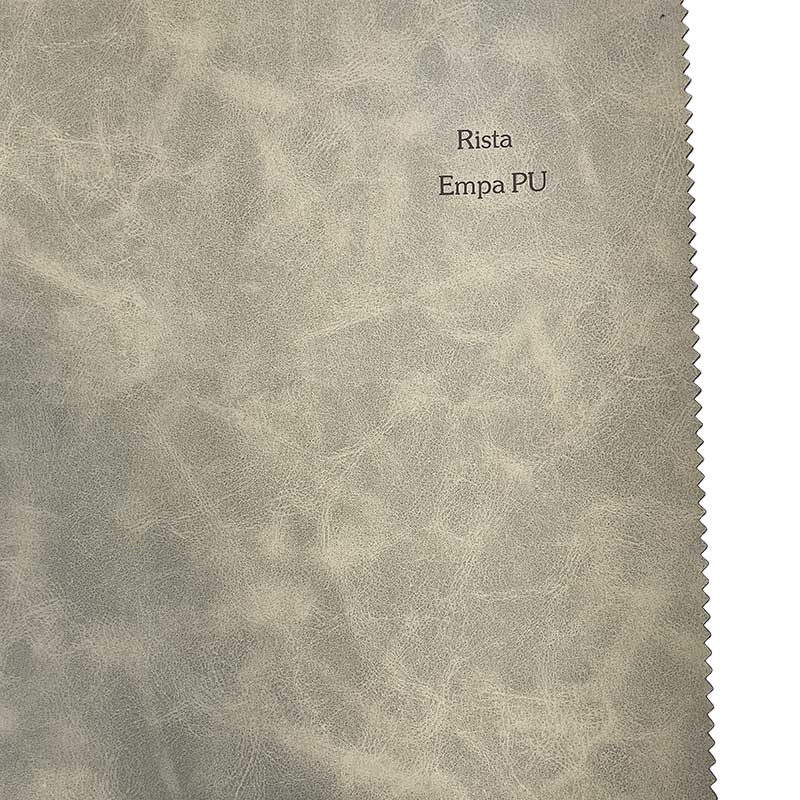

2. Faux Leather

Faux leather, made from synthetic materials, is an excellent alternative for those looking for a cruelty-free option. It can be heat pressed successfully and is available in a variety of colors and textures.

3. Suede

Suede can also be heat pressed, but caution is needed due to its delicate texture. Ensure that the temperature is set appropriately to avoid damaging the material.

4. Specialty Leather

Specialty leathers, such as embossed or metallic options, can provide unique finishes. It is essential to test these types before full application to ensure they can withstand the heat press process.

Essential Tools and Equipment for Heat Pressing

To successfully heat press leather sheets, you will need a few essential tools and equipment:

1. Heat Press Machine

Investing in a high-quality heat press machine is vital. Look for one that offers adjustable temperature and pressure settings for optimal control.

2. Teflon Sheets

Teflon sheets protect the leather from direct contact with the heat plates, preventing scorching and ensuring even heat distribution.

3. Design Software

Using design software allows you to create and customize your graphics before printing. Popular choices include Adobe Illustrator and CorelDRAW.

4. Heat Transfer Vinyl or Transfers

Choose high-quality heat transfer vinyl (HTV) or pre-made transfers that are compatible with leather. Ensure they are designed for heat pressing to achieve the best results.

5. Cutting Machine

A cutting machine, such as a Cricut or Silhouette, can help you create precise designs and shapes from HTV or other materials.

Step-by-Step Guide to Heat Pressing Leather Sheets

Now that we have covered the basics, let’s delve into the step-by-step process of heat pressing leather sheets:

Step 1: Prepare Your Design

Create or select your design using graphic design software. Ensure that the design is mirrored if you’re using heat transfer vinyl.

Step 2: Cut Your Design

Use a cutting machine to carefully cut out your design from the chosen material. Take your time to ensure accuracy.

Step 3: Preheat the Heat Press

Set your heat press to the recommended temperature for the type of leather you are using. Preheating allows for consistent results.

Step 4: Position the Leather Sheet

Place your leather sheet on the heat press, ensuring it is smooth and free from wrinkles. This step is important for an even application.

Step 5: Apply the Design

Position your cut design on the leather sheet, taking care to align it properly. Use Teflon sheets to cover the design before pressing.

Step 6: Heat Press the Design

Close the heat press and apply the recommended pressure for the designated time. Follow the instructions for your specific heat transfer material.

Step 7: Allow to Cool

Once the pressing is complete, carefully open the heat press and allow the leather to cool. This process helps set the design properly.

Step 8: Peel and Finish

Peel away the backing from the design. If necessary, repeat the pressing process to ensure the design is fully adhered.

Troubleshooting Common Heat Pressing Issues

Even experienced artisans may encounter challenges when heat pressing leather sheets. Here are some common issues and solutions:

1. Design Peeling Off

If your design peels off, it may be due to insufficient heat or pressure. Double-check your settings and consider re-pressing the design.

2. Scorched Leather

Scorching can occur if the temperature is too high. Always use Teflon sheets and monitor the heat settings carefully.

3. Incomplete Transfers

If parts of the design do not transfer properly, it could be due to an uneven surface. Ensure the leather is flat and free of debris before pressing.

4. Color Fading

Color fading over time may result from using low-quality materials. Invest in high-quality heat transfer vinyl to ensure longevity.

Creative Uses for Heat Pressed Leather Projects

The possibilities are endless when it comes to heat pressing leather. Here are some creative applications to inspire your next project:

1. Personalized Gifts

Create custom leather wallets, keychains, or bookmarks as thoughtful gifts for friends and family.

2. Fashion Accessories

Design unique leather bags, belts, or shoes with personalized graphics that reflect individual style.

3. Home Décor

Heat press leather sheets onto cushions, wall art, or coasters to add a touch of elegance to your space.

4. Branding Opportunities

Businesses can utilize heat pressing to create branded merchandise, such as patches, tags, or promotional items.

5. Custom Pet Products

Craft personalized leather collars or leashes for pets, showcasing their names or unique designs.

Conclusion

Heat pressing leather sheets opens up a world of creative possibilities for artisans and crafters. By understanding the techniques, tools, and materials involved, you can transform your leather projects into stunning works of art. With careful attention to detail and the right approach, you can achieve professional results that elevate your craftsmanship. Whether you're looking to create personalized gifts, unique fashion items, or innovative home décor, heat pressing allows you to express your creativity and skill like never before.

FAQs About Heat Pressing Leather Sheets

1. Can I heat press synthetic leather?

Yes, synthetic leather is suitable for heat pressing, but ensure the temperature settings are appropriate for the material.

2. What temperature should I use for heat pressing leather?

The temperature may vary based on the type of leather and heat transfer material. Generally, temperatures range from 275°F to 350°F.

3. How long should I press the leather?

Pressing time can differ depending on the material used. It typically ranges from 10 to 30 seconds.

4. Is it necessary to use a Teflon sheet?

While not mandatory, using a Teflon sheet helps protect the leather and ensures even heat distribution.

5. Can heat pressed designs be washed?

Yes, heat pressed designs can be washed, but it’s essential to follow care instructions specific to the materials used.